COVID-19 Update, October 2020

During this challenging time, we are focused on protecting the health of our employees and their families, but we are also open to serve our customers as normal.

We have implemented controls on our facility including daily sanitizing of our facility and verifying daily that our employees are not exhibiting any symptoms associated with COVID-19. We are limiting non-employee access to the building and have posted all entrances with our phone number to call for someone to handle pickups and deliveries. We are still picking up and delivering equipment and have added steps to disinfect equipment coming in and leaving our facility. We understand that this time may be challenging for those supporting critical infrastructure and we are prepared to address emergency service needs.

We realize that circumstances are changing rapidly, so we’ll continue to monitor the situation and keep you updated if there are any impacts on our operations. Please stay safe and let us know if you need any technical help through the coming weeks and thereafter.

For 24 hour support, please call 724-746-4700.

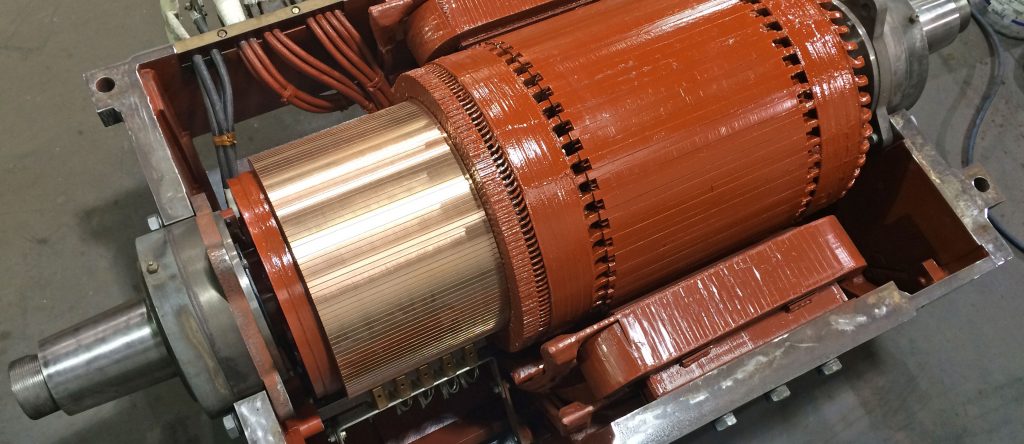

United Industrial Celebrates its 65th Year and Expands Leadership Team

Scott Wilshire joins United as VP and Chief Operating Officer.

Koyo Training Seminar

What a great day at United last Friday was. Over sixty of our customers attended the Bearing Seminar that we

presented in conjunction with KOYO Bearing. A day of Training…Good Food… and Plant Tours.